About

Runwo Environmental Protection Technology

Changzhou Runwo Environmental Protection Technology Co., Ltd., established in April 2011, is located in the core area south of Changzhou City, Jiangsu Province. Its convenient transportation network allows for rapid connection to regional transportation arteries, providing efficient support for raw material transportation and product delivery. The company boasts standardized factory buildings covering a total area of 12,500 square meters. The production workshop is equipped with multiple professional overhead cranes, with a maximum lifting capacity of 100 tons, fully meeting the needs of heavy-duty component production.

Leveraging its comprehensive hardware facilities, the company has built a fully integrated manufacturing capability, covering key processes such as material cutting, shearing, bending, rounding, welding, shot blasting, painting, machining, and assembly. This enables end-to-end operations from raw material processing to finished product assembly, effectively ensuring product precision and production efficiency.

Since its inception, the company has focused on the research and development and manufacturing of mechanical equipment components for various industries. Leveraging its solid technical capabilities and stringent quality control, its business scope has broadly covered multiple fields including metallurgical machinery, environmental protection machinery, textile machinery, construction machinery, power equipment, papermaking equipment, building steel structures, single crystal furnaces, medical equipment, hydropower, nuclear power, cranes, ships, various machine tools, and automation equipment. The company provides customized and highly adaptable component solutions for customers in different industries, helping them improve equipment performance and production efficiency.

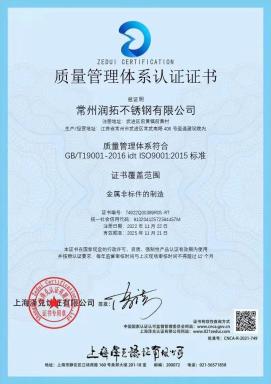

The company adheres to the philosophy that “quality is the foundation of survival, and service is the basis of development.” It has obtained ISO9001 quality management system certification and IATF16949 automotive industry quality system certification, establishing a comprehensive quality control process from raw material warehousing to finished product delivery, ensuring a product qualification rate consistently above 99.8%. In the future, Changzhou Runwo Technology Environmental Protection Co., Ltd. will continue to increase investment in equipment upgrades and technology research and development, focusing on the processing of high-precision and complex parts, and continuously improving service response speed and customization capabilities. It is committed to becoming a “customer-trusted and industry-recognized” machining partner, injecting momentum into the high-quality development of the global equipment manufacturing industry.

Material cutting

Equipped with 20kW laser cutting systems for high-precision plate and pipe cutting.

Folding plate & circle

We have a 10,000-ton hydraulic press for bending and rolling heavy plates up to 280mm thickness.

Welding

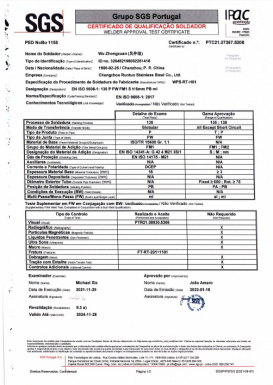

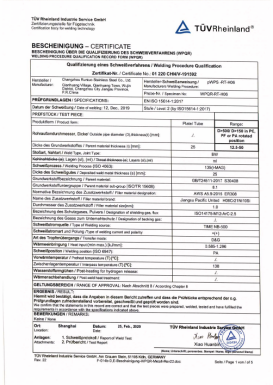

Multiple welding processes including MIG, TIG, and submerged arc welding, certified by ISO9606.

Machining

Max 6.5m × 24m gantry milling machines enable precise machining of large and heavy parts.

Detection

Equipped with Zeiss CMM and Hexagon laser tracker for full product inspection and quality assurance.

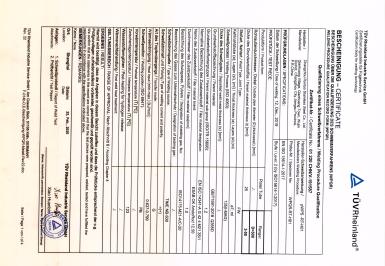

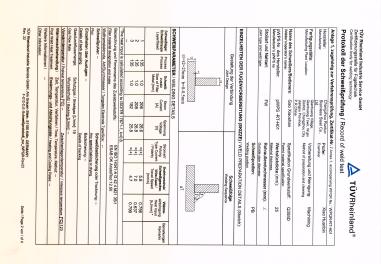

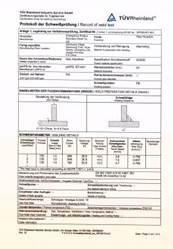

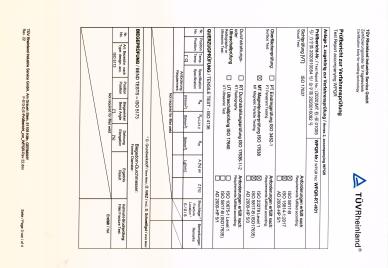

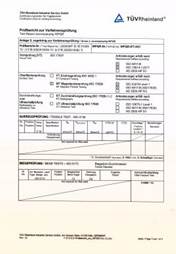

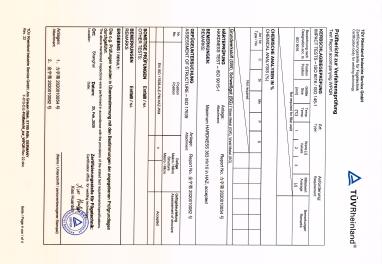

Qualifications

Metallurgical key parts—certified and verifiable.

Service Standards

Delivery standards built for metallurgical lines.

Drawing-Based Customization & OEM Supply

We build to your drawings and specifications, with OEM labeling support. From material sourcing to machining and assembly, we follow your standards to reduce multi-supplier coordination risk.

Quality Control Loop & Acceptance-Ready Inspection

Incoming inspection → in-process control at key steps → final inspection. Precision measurement (e.g., CMM) verifies critical dimensions and tolerances, with traceable records for acceptance.

Export-Safe Packaging & Stable Delivery

Reinforced packing is designed for long-distance transportation to prevent impact damage, reducing rework on site and helping keep installation schedules on track.