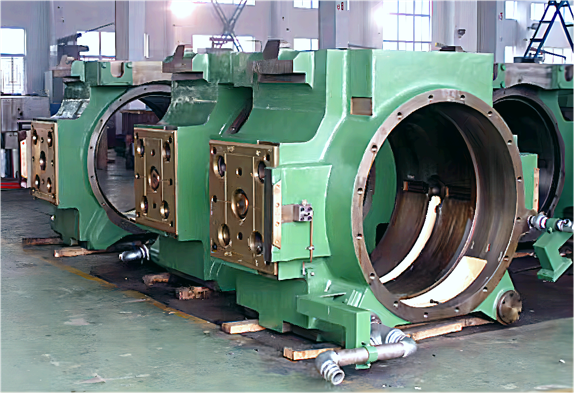

Bearing Chock

Rolling mill bearing housing

A Rolling Mill Bearing Chock (Bearing Housing) supports roll neck bearings and transfers rolling forces through the mill stand. In hot rolling, bearing housings operate under heavy load, vibration, heat, and contamination, so geometric accuracy is essential for stable bearing performance.

Product Description

A Rolling Mill Bearing Chock (Bearing Housing) supports roll neck bearings and transfers rolling load to the mill stand structure. In hot rolling, bearing chocks define bearing alignment, load distribution, and the stability of roll positioning under heavy dynamic load.

From a system interface perspective, the bearing chock is a precision alignment component. Engineers focus on bearing bore roundness, concentricity to reference datums, squareness of end faces, and positional accuracy of locating features. Any deviation affects bearing load distribution, increases heat generation, and shortens bearing service life.

For acceptance, key inspection items include bearing seat geometry, concentricity, face squareness, and interface positional tolerance. At RFQ stage, providing stand position, bearing type, roll neck dimensions, sealing arrangement, and lubrication system details allows machining tolerances and inspection plans to be defined to reduce installation adjustment and improve reliability.