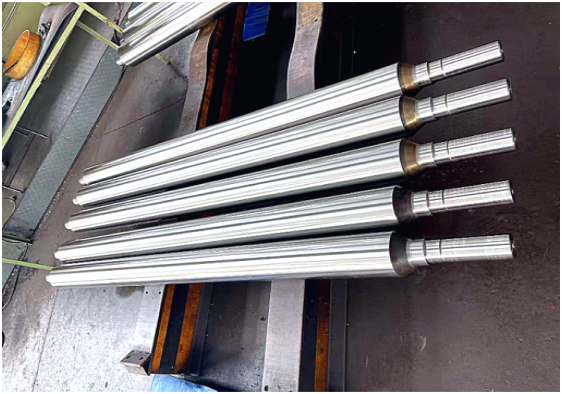

Work Roll

Hot Strip Mill Work Roll

A Hot Strip Mill Work Roll is the primary tool that directly contacts the strip and controls thickness, profile, and surface condition as the material passes through the finishing stands. In the hot rolling section, stable roll geometry supports consistent rolling force and helps reduce vibration-related defects.

Product Description

A Hot Strip Mill Work Roll operates in the finishing stands of the hot rolling section, directly controlling strip thickness, profile, and surface condition. As the final forming tool in the rolling pass, work roll geometry influences rolling force stability, strip shape control, and surface quality before cooling and coiling.

From an engineering standpoint, the work roll is evaluated as a geometry-controlled rotating tool. Key concerns include barrel profile accuracy, runout, crown design, neck geometry, and surface integrity. Small deviations can manifest as thickness variation, chatter, or accelerated wear, directly affecting product quality and roll campaign life.

For procurement and acceptance, focus is typically placed on diameter tolerance, runout control, barrel profile accuracy, and documented inspection records linked to the roll ID. At RFQ stage, providing stand position, rolling force range, strip width, target grades, and historical wear patterns allows geometry and inspection requirements to be aligned with mill operation.